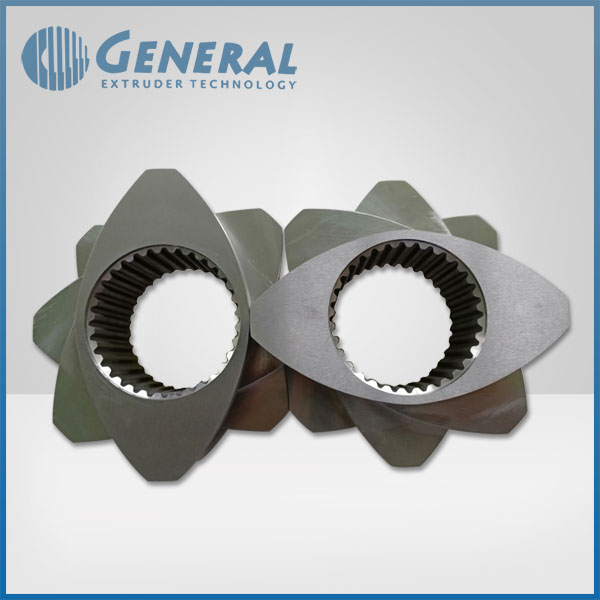

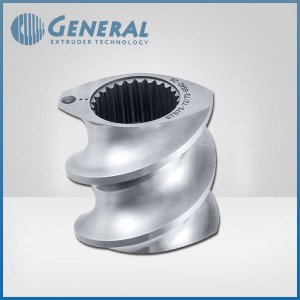

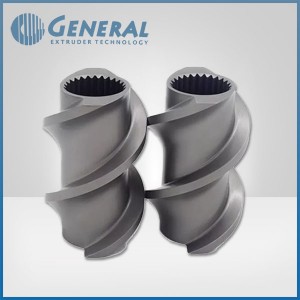

Twin Screw Extruder Machinery Screw Elements , Food Extruder Machine Parts

| Product Name: | Screw Elements | Application: | Twin Screw Extruder |

|---|---|---|---|

| Out Diameter: | More Than 40 Mm | HRC: | 58-62 |

| Standard: | Match Original Design | Type: | Coveying Element |

Twin Screw Extruder Machinery Screw Elements , Food Extruder Machine Parts

Screw Elements Description:

· convenient interchangeability by agile combination.

· fulfill efficient self-cleaning, transmission, compounding, pressure-forming, etc.

· made of high tool speed W6Mo5Cr4V2, or anti-corrosion steel 38CrMoAlA by special treatment.

Assembled together, they will become twin screw which are essential and key part of extruders for material to

transmission, shearing and plasticization.

Screw Elements Applications:

| Code no | Remarks | Hardness | Wear | Corrosive | Application |

| Gen-06 | Ingot high speed steel | HRC-59-62 | 5 | 2 | Engineering Plastics, Wear Resistance |

| Gen-11 | Ingot Die Steel, SKD11 / D2/1.2379 | HRC-58-63 | 4 | 2 | General Plastics |

| Gen-44 | Stainless steel SUS440 | 3 | 6 | Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-09 | CPM9V | 6 | 6 | Engineering Plastics,High Wear Resistance | |

| Gen-10 | Powder high spped steel X245/SAM10 | HRc 61 ~ 65 | 8 | 3 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

| Gen-39 | X235/SAM39 | 6 | 8 | Super Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-60 | ASP60/MM60 | 9 | 9 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

Our Advantages:

a. Cost advantage: mature scientific processing technology and heat treatment process to produce high-quality thread components, barrels, to replace imported products, to reduce costs for customers.

b. Advantages of foreign trade: Many well-known enterprises at home and abroad extruder screws are manufactured by customers and serve for many years. SABIC, LG Chem, Guangdong Hyundai, Tianjin Samsung, Formosa Plastics, DuPont, and Shanghai Toyoink are all cooperative customers. Can make a presentation, such as the company’s gift, reflected in About US.

c. Manufacturing advantages: at the top of domestic production level, to meet the production standards of Japan and Germany. Strict product quality inspection procedures

d. Time cost advantage: the product itself can be customized according to customer needs, and the delivery time is short, the cycle is flexible and efficient.

Competitive Advantage:

All dimensions including out diameter, Hole size tolerance, Root diameter,Parallelism of end surface,Verticality are in accordance with technical data.