Non Flanged Injection Molding Machine Screw Multiple Purpose Agile Combination

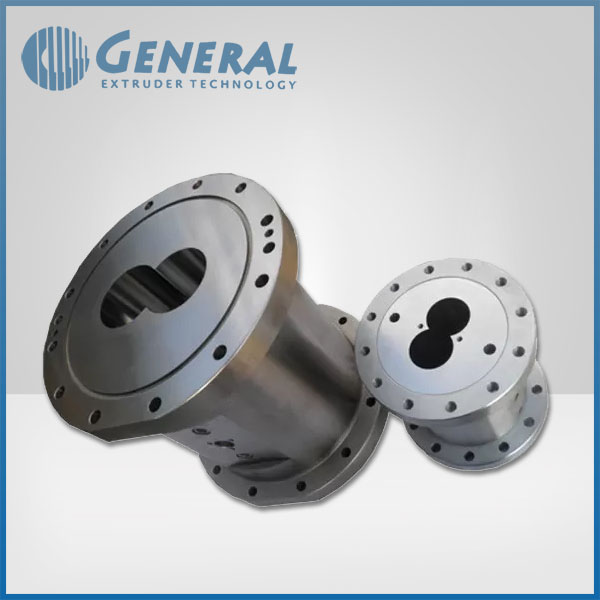

| Product Name: | Combi Barrel For W&P Coperion ZSK58MC | Application: | Polymer Compouding |

|---|---|---|---|

| Out Diameter: | 25-130mm | Material: | HIP Powder Metal |

| HRC: | 58-62 | Feature: | High Anti-wear |

| Standard: | Match Original Design | Type: | Combi Barrel (top And Side Open) |

Round barrel for Berstorff ZE series

Specifications:

General manufacture replacement barrel parts for all configurations including:

- Round

- Rectangle

- Flanged

- Non-Flanged

- Attached is Round barrel for Berstorff ZE series we make for compounders.

Presales service:

> introducing in detail features and application of the products to customer

> Selecting economical and practical machine & equipment for customer

> Providing operation data of the related machine & equipment

> Providing means of trial performance for customer

Sales service: Recommending engineering conditions required for installation of the machine & equipment

Communicating in time the manufacturing progress of the machine with user

Providing assistance in technical conditions, screw combination and barrel dispositionneeded for product

Description:

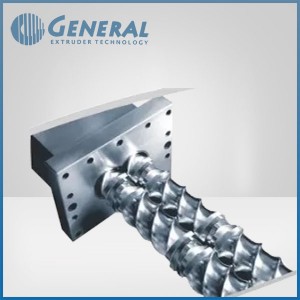

We are the first screw element manufacturer in China, with more than 20 years’ manufacturing experience, our screw element,barrel, shaft are produced by HIP material import from Germany to be same anti-wear& anti-corrosion , our customer including Europe extruder manufacturers, and world’s leading polymer compounders like Aschulman,Polyone,Covestro,DSM enginering plastic ,Lanxess.

Any questions,please feel free to contact us.

Applications:

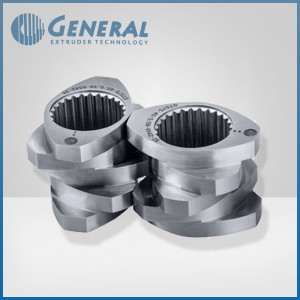

| Code no | Remarks | Hardness | Wear | Corrosive | Application |

| Gen-00 | Nitride steel | HV-950-1100 | 3 | 2 | General Plastics |

| Gen-06 | Ingot high speed steel | HRC-59-62 | 5 | 2 | Engineering Plastics, Wear Resistance |

| Gen-11 | Ingot Die Steel, SKD11 / D2/1.2379 | HRC-58-63 | 4 | 2 | General Plastics |

| Gen-44 | Stainless steel SUS630 | 3 | 6 | Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-09 | CPM9V | 6 | 6 | Engineering Plastics,High Wear Resistance | |

| Gen-10 | Powder high spped steel X245/SAM10 | HRc 61 ~ 65 | 8 | 3 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

| Gen-39 | X235/SAM39 | 6 | 8 | Super Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-60 | ASP60/MM60 | 9 | 9 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

Competitive Advantage:

All dimensions including out diameter, Hole size tolerance, Root diameter,Parallelism of end surface,Verticality are in accordance with technical data.