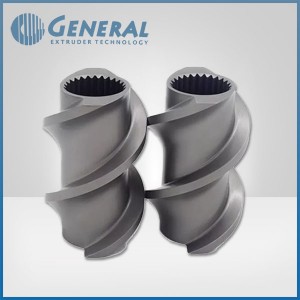

Nickel Alloy Extruder Screws And Barrels Agile Combination Segmented Energy Efficiency

| Product Name: | Screw Element For Toshiba TEM58BS | Application: | Polymer Compouding |

|---|---|---|---|

| Out Diameter: | 58mm | Material: | High Speed Steel |

| HRC: | 58-62 | Feature: | High Anti-wear |

| Standard: | Match Original Design | Type: | Standard |

| High Light: |

extruder parts, mechanical screw |

||

screw element for Toshiba TEM58BS

Specifications:

For high-acid and F46 environment,Hastelloy C-276(00Cr16Mo16W4) will be sutiable.It’s an extremely anticorrosive nickel alloy that is used to manufacture the screw elements ofToshiba TEM58BS with high anti-corrosion quality.

Description:

We are the first screw element manufacturer in China, with more than 20 years’ manufacturing history, our screw element, Kneading block,barrel, shaft are produced by HIP material import from Germany to be same anti-wear& anti-corrosion , our customer including Europe extruder manufacturers, and world’s leading polymer compounders like Aschulman,Polyone,Covestro,DSM enginering plastic ,Lanxess.

Applications:

| Code no | Remarks | Hardness | Wear | Corrosive | Application |

| Gen-00 | Nitride steel | HV-950-1100 | 3 | 2 | General Plastics |

| Gen-06 | Ingot high speed steel | HRC-59-62 | 5 | 2 | Engineering Plastics, Wear Resistance |

| Gen-11 | Ingot Die Steel, SKD11 / D2/1.2379 | HRC-58-63 | 4 | 2 | General Plastics |

| Gen-44 | Stainless steel SUS440 | 3 | 6 | Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-09 | CPM9V | 6 | 6 | Engineering Plastics,High Wear Resistance | |

| Gen-10 | Powder high spped steel X245/SAM10 | HRc 61 ~ 65 | 8 | 3 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

| Gen-39 | X235/SAM39 | 6 | 8 | Super Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-60 | ASP60/MM60 | 9 | 9 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

Competitive Advantage:

All dimensions including out diameter, Hole size tolerance, Root diameter,Parallelism of end surface,Verticality are in accordance with technical data.