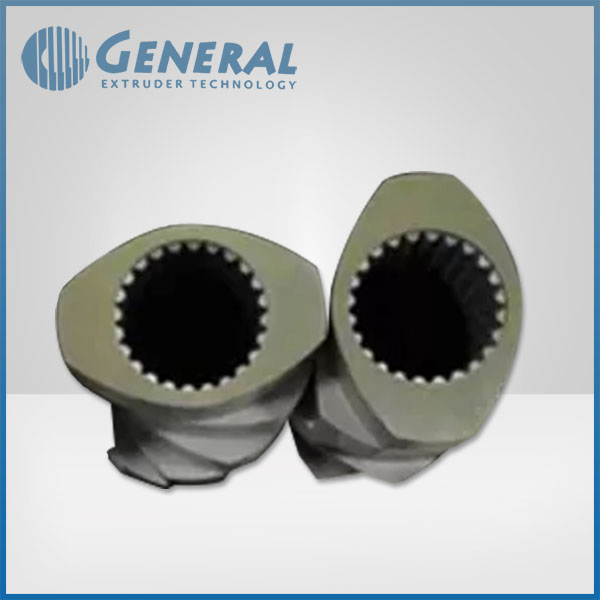

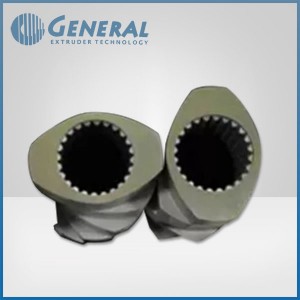

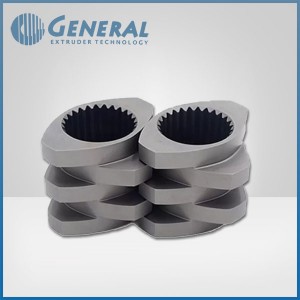

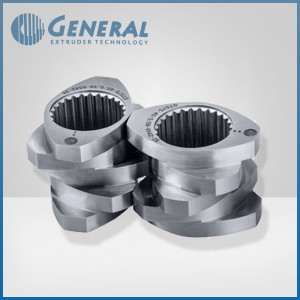

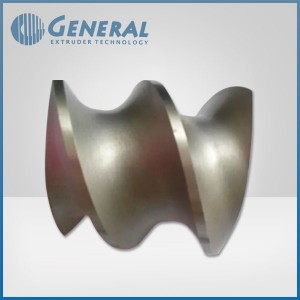

Integral Type Twin Screw Extruder Elements Conical For Toshiba TEM37BS

| Product Name: | Theysohn Screw Element | Application: | Polymer Compouding |

|---|---|---|---|

| Out Diameter: | 37mm | Material: | High Speed Steel |

| HRC: | 58-62 | Feature: | High Anti-wear |

| Standard: | Match Original Design | Type: | Coveying Element |

| High Light: |

extruder parts, mechanical screw |

||

screw element for Toshiba TEM37BS

Specifications:

Hip material from Europe(highly wear-resistance powder metallurgical steel)-Gen-10 is applied to manufacturing of Toshiba TEM37BS screw element. Because of extremely high wear-resistance, high torque and anti-popping, this material is often used to manufacturing international advanced twin-screw extruder which can stand the high-wearing environment. For example, produce the engineering plastic with more than 50% fiber.

Description:

We are the first screw element manufacturer in China, with more than 20 years’ manufacturing history, our screw element, Kneading block,barrel, shaft are produced by HIP material import from Germany to be same anti-wear& anti-corrosion , our customer including Europe extruder manufacturers, and world’s leading polymer compounders like Aschulman,Polyone,Covestro,DSM enginering plastic ,Lanxess.

Applications:

| Code no | Remarks | Hardness | Wear | Corrosive | Application |

| Gen-00 | Nitride steel | HV-950-1100 | 3 | 2 | General Plastics |

| Gen-06 | Ingot high speed steel | HRC-59-62 | 5 | 2 | Engineering Plastics, Wear Resistance |

| Gen-11 | Ingot Die Steel, SKD11 / D2/1.2379 | HRC-58-63 | 4 | 2 | General Plastics |

| Gen-44 | Stainless steel SUS440 | 3 | 6 | Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-09 | CPM9V | 6 | 6 | Engineering Plastics,High Wear Resistance | |

| Gen-10 | Powder high spped steel X245/SAM10 | HRc 61 ~ 65 | 8 | 3 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

| Gen-39 | X235/SAM39 | 6 | 8 | Super Engineering Plastics, Corrosive Resistance for Filler, FG Filler | |

| Gen-60 | ASP60/MM60 | 9 | 9 | Super Engineering Plastics, Wear Resistance for Filler, FG Filler |

Competitive Advantage:

All dimensions including out diameter, Hole size tolerance, Root diameter,Parallelism of end surface,Verticality are in accordance with technical data.